| Product Literature |

| 2D Product Drawings |

| Applications |

A full range of apparatus used for |

| Quick Links |

|

• Vessel Selection Guide (New) • Compare: Hi Temp Press. Closure • Advantage: Reactor Port Connect • Download: Product Literature Parker Autoclave Business Units |

| Location Path |

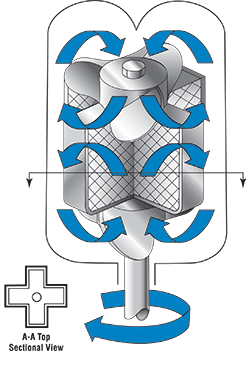

Carberry Spinning Catalyst Basket Reactor Catalyst basket has a “cruciform” cross-section |

||

|

|

|

FEATURES

BENEFITS Corrosion resistant gradientless reactor is basic equipment for advancing the science of gas phase, solid phase, heterogeneous catalyst technology.

|