FEATURES

- Reactants:

Gas/Liquid/Solids, Vapor/Liquid/Solids.

- Typical Reactions:

Hydrocarbon petroleum studies, hydro-liquefication, catalyst testing.

- Basket Screen:

14 x 14 mesh, 0.020” (0.51 mm) wire and a nominal opening size of 0.051” (1.3 mm)

- Inside Diameter:

1 in. (25.4 mm)

- Basket Volume:

2.2 in.³ (35 cm³)

- Free Volume:

30 in.³ (500 cm³)

- Maximum Allowable Working Pressure:

5,500 psig (379 Bar)

- Temperature:

650ºF (343ºC)

- Maximum Rotation Speed:

1,500 RPM. The catalyst and fluid loads may unbalance or overstress the bearings. A typical rotation speed range is 100 to 1,500 RPM.

- Common Customizations:

Special wire mesh size, special materials, specific pressure/temperature ratings, ASME code stamp, CE mark for Pressure Equipment Directive,

and CRN.

- Standard Material:

316 Stainless Steel

BENEFITS

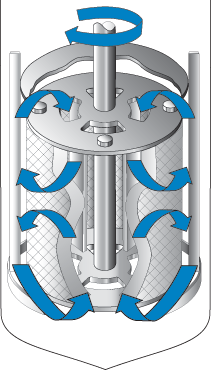

Corrosion resistant gradientless reactor is basic equipment for advancing the science of gas phase, solid phase, heterogeneous catalyst technology.

This high pressure laboratory apparatus can be used for diverse supported and selective catalyst research, including catalyst screening, catalyst characterization, and surface chemistry studies. The leak-free metal gasket design provides bench-scale catalytic synthesis capability for scientific experimentation.

|