| Product Literature |

| 2D Product Drawings |

| Applications |

Components used in all aspects of high pressure flow systems. |

| Quick Links |

|

• Vessel Selection Guide (New) • Compare: Hi Temp Press. Closure • Advantage: Reactor Port Connect • Download: Product Literature Parker Autoclave Business Units |

| Location Path |

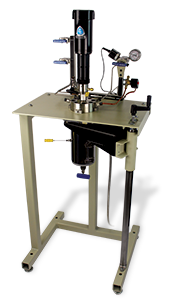

EZE-Seal® Stirred Laboratory Reactors Seal this (100 to 4,000ml) high pressure laboratory reactor with low torque |

||

|

|

|

FEATURES

BENEFITS Ease of cleaning & elimination of foot bearings reduces the risk of cross-contamination. It offers easy access for high pressure & high temperature, chemical synthesis of corrosive, hazardous & very reactive chemicals / petrochemicals as well as solvothermal reactions. It is delivered custom configured & after full functional testing for fast & easy start-up. See ZipperClave® Reactors for pressures up to 2,200 psi (151 bar). See Bolted Closure Reactors for pressures up to 5,000 psi (379 bar).

|