| Product Literature |

| Not Available |

| 2D Product Drawings |

| Applications |

Custom designed, multiple reactor systems or bench top, oven based, reaction equipment. |

| Quick Links |

|

• Vessel Selection Guide (New) • Compare: Hi Temp Press. Closure • Advantage: Reactor Port Connect • Download: Product Literature Parker Autoclave Business Units |

| Location Path |

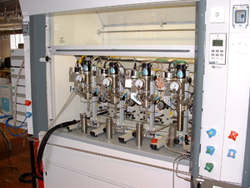

Multi-Reactor Systems Laboratory reactor system simulates production chemical processes |

|

Parker Autoclave Engineers integrates custom, automatic controls with high temperature & high pressure, laboratory reactors into a pressure reactor system for chemical / petrochemical research. |

|

FEATURES

BENEFITS Simulate a complete chemical plant in a laboratory scale. Evaluate new chemistries & processes in a cost-effective model of production chemical equipment. Automatic control increases repeatability in complex chemical processes. Allowing unattended 24 hour 7 day per week operation increases productivity. Labor costs are reduced since the process sequence, process control & data logging are automated. Increase accuracy of the research by using actual data & avoid transcription. |